Details

Understanding wood veneer

05 Jul 2021In our previous blog we covered the key differences between wood & wood like surfaces: Melamine, Laminate, Veneer - Know the difference. Considering trees are cut down across forests at an alarming rate to create furniture and for other applications, it's important to understand the difference in quality, availability and price to best suit your space.

Let’s address some of the basics first:

What is wood veneer?

Wood veneer is a thin layer of natural wood that is approximately 0.4mm to 2.5mm thick. This is usually bonded with a substrate that could be either MDF (Medium Density Fiberboard), Particle Board or Plywood.

Should I buy furniture made of solid wood or veneer?

Solid wood is used less frequently in construction today for a variety of reasons. The product is usually heavier because the raw material as the name suggests is solid wood while veneered products are usually bonded to a lighter substrate. The price of a solid wood product is usually also more expensive compared to a veneer product of the same application.

Luxurious residential furniture has a higher likelihood of being produced in solid wood due to the expectation of the products lifespan while veneered products are more likely to be used in corporate and hospitality projects where a refurb is imminent within five to ten years.

Live wood tables however have recently gained popularity in hospitality & commercial projects as meeting tables or touch down collaboration tables to create a sense of wellness. Live wood surfaces are cut right out of a trunk of the tree and sealed with resin to make the surface impervious to moisture and liquids.

Why are the prices for wood veneer so different?

Wood Veneers are a feature of a tree. Some trees grow quickly and are in abundance, while other trees like Ebony & Rosewood are some of the most expensive woods to procure as it takes anywhere between 20 to 200 years for it to reach its maturity. Oak, Walnut, Cherry & Maple are some of the more common veneers used in furniture today

Understanding the different cuts or patterns of veneer?

The pattern featured on the veneer is largely due to the way the veneer sheet is cut from the log of the tree. Below are some of the common examples of veneer cuts available

- Rotary Cut - The blade cuts around the circumference of the log

- Quarter Cut - The log is cut into quarters and sliced perpendicular to the log rings

- Rift Cut - The quarter cut log is cut across the log rings creating accentuated lines

- Crown Cut - The half cut log is cut parallel to the centre of the log and at a tangent to the growth rings

- Half Round Cut - Similar to a rift cut, the blade runs across a half cut log

Ref:https://www.bord.com.au/resources/timber-veneer-cuts/

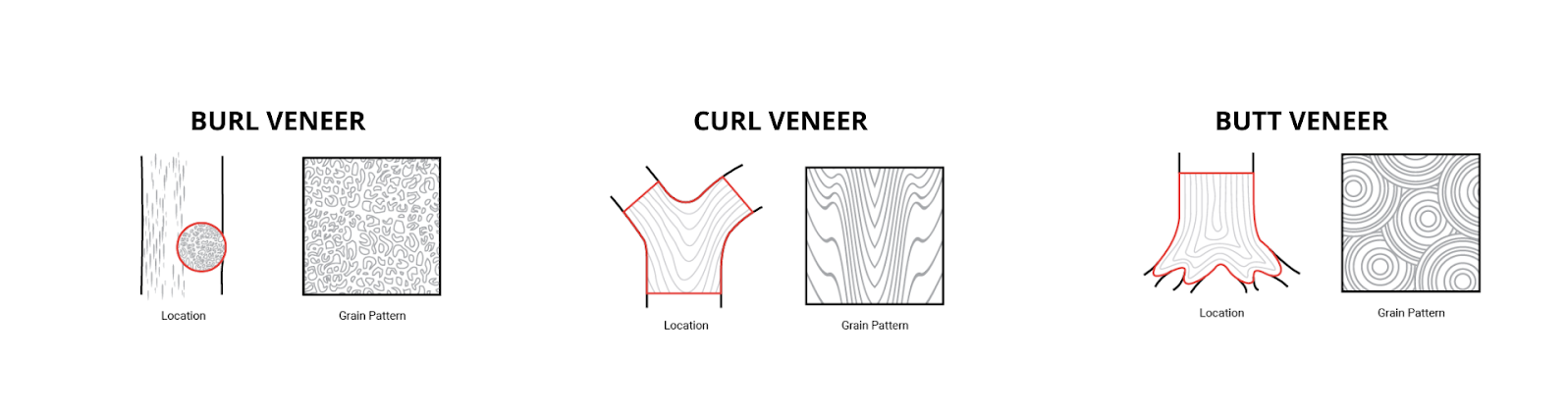

- Burl Veneer - Is a pattern as a result of a round growth on a tree bark that creates deformed grain structure.

- Curl Veneer - Is a pattern found at the juncture of a tree bark splitting into two separate limbs

- Butt Veneer - Is created as a result of cutting across the log creating a circular pattern

Ref:https://www.bord.com.au/resources/timber-veneer-cuts/

Matching and constructing using veneer

Wood veneer gets stored & transported in sheets which usually means you have to join two or more sheets to create a work surface using glue or other methods. There are various patterns created using different cuts of veneer and joining types.

Some of the common matching techniques are:

- Book Matching

- Slip & Reverse Matching

- Random Match

- Quarter Matching

Ref:https://www.bord.com.au/resources/timber-veneer-matching/

Some high end products require special joins these include:

- V MAtch

- Herringbone

- Sunburst

Ref:https://www.bord.com.au/resources/timber-veneer-matching/

Meeting, executive and coffee tables are usually covered with veneers to accentuate the application, while workspaces use laminate due to the durability required for high traffic usage.

Wood veneers are higher in price when compared to laminate or melamine furniture however they more than make up with the ability to customize grain details and colour shades to achieve your ideal design.

The Total Office:

As a provider of workspace solutions, The Total Office helps elevate the work experience of its customers by addressing collaboration, acoustics, environmental sustainability and well being at the design stage using globally recognized products and tools. This enables its customers to raise their productivity in the workspace laying a foundation for innovation and a sound work culture. The Total Office is Headquartered in Dubai, UAE serving the country and the wider Middle East region. For more information visit: www.thetotaloffice.com

Reference

https://www.bord.com.au/product-category/plywood

https://brandalyzer.blog/2018/08/19/laminate-vs-veneers-and-plyboard-vs-mdf-vs-particleboard/

https://answerstoall.com/miscellaneous/why-is-wood-veneer-so-expensive/

https://www.amishoutletstore.com/blog/difference-between-laminate-veneer-solid-wood-furniture/

https://www.bord.com.au/resources/timber-veneer-cuts/

http://eurogroupbelcaire.com/veneer-cuts/

https://www.bord.com.au/resources/timber-veneer-matching/

http://eurogroupbelcaire.com/veneer-species/

http://eurogroupbelcaire.com/veneer-figure-types/